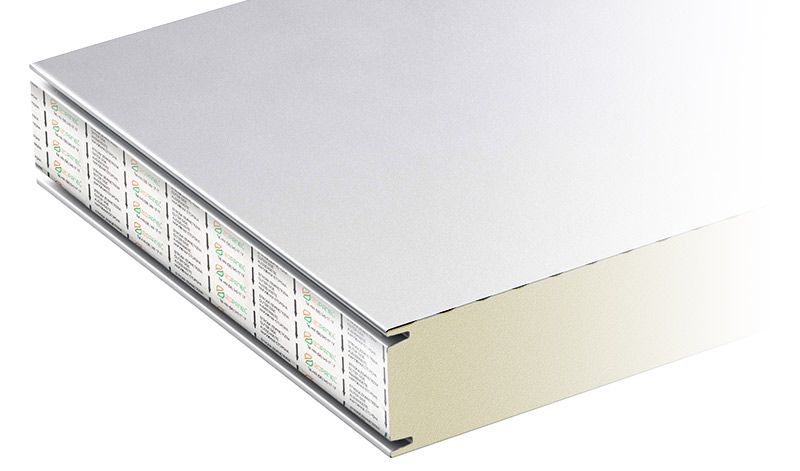

IzoWall EPS

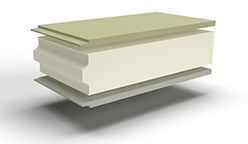

A wall sandwich panel with a polystyrene core

IzoWall EPS

- Energy efficiency ensured by core made of self-extinguishing polystyrene foam

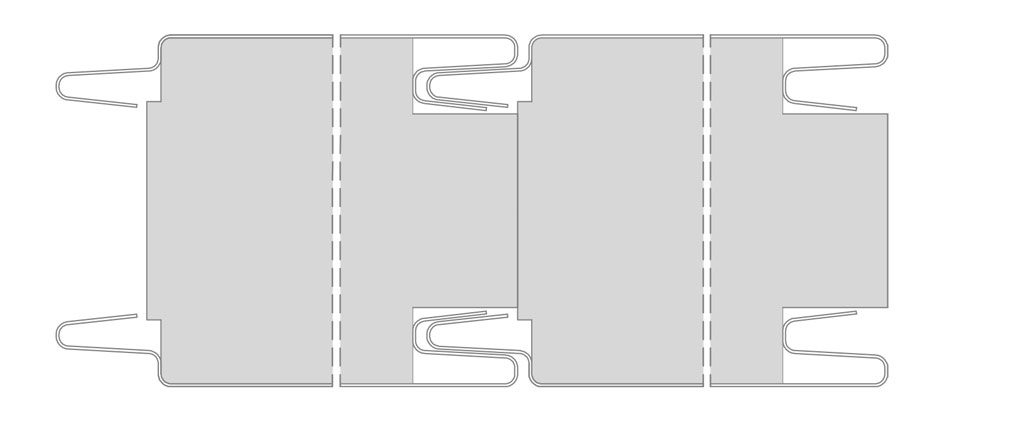

- Easy installation ensured by profiled edges

- Tightness ensured by double panel lock

- Durability of protective coatings on claddings ensured by large bend radii

- Surface aesthetics – wide range of colours and variety of profile types

- It is possible to order a single-side cladding panel

Sandwich panel as a modern product with various cores and of various thickness combined with specialized polyester protective coating FarmCoat has been designed in particular for use on roofs and walls of livestock facilities (e.g. pig, hen, cow houses) and other agricultural facilities (e.g. barns, stores, mushroom farms).

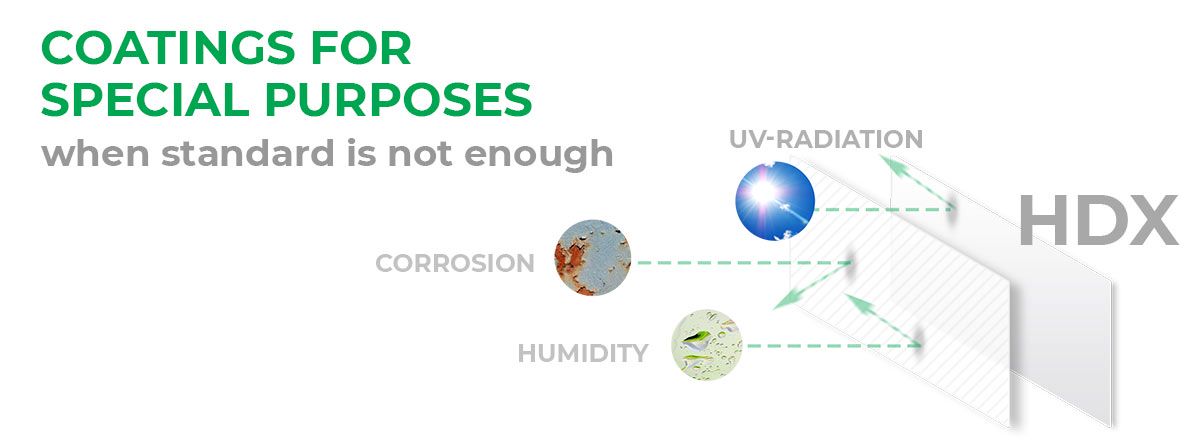

Specialized FarmCoat coating providing resistance to ammonia, urine and fertilizers may extend the building life twice and thus reduce cost of its use.

Industry is one of the most important branches of the global economy. Thanks to our products we provide You with energy-efficient claddings ensuring high quality, while being a reliable, long-lasting construction material. Use of proper cores in sandwich panels meets requirements of Polish and European legislation on fire safety in a facility and provides insulation of a facility in accordance with the highest standards. Specialized coatings make it possible to install our sandwich panels in any weather conditions, while meeting requirements of all corrosion classes. Construction and shape of panel lock ensure easy and fast installation what provides for time savings and possibility of dynamic construction.

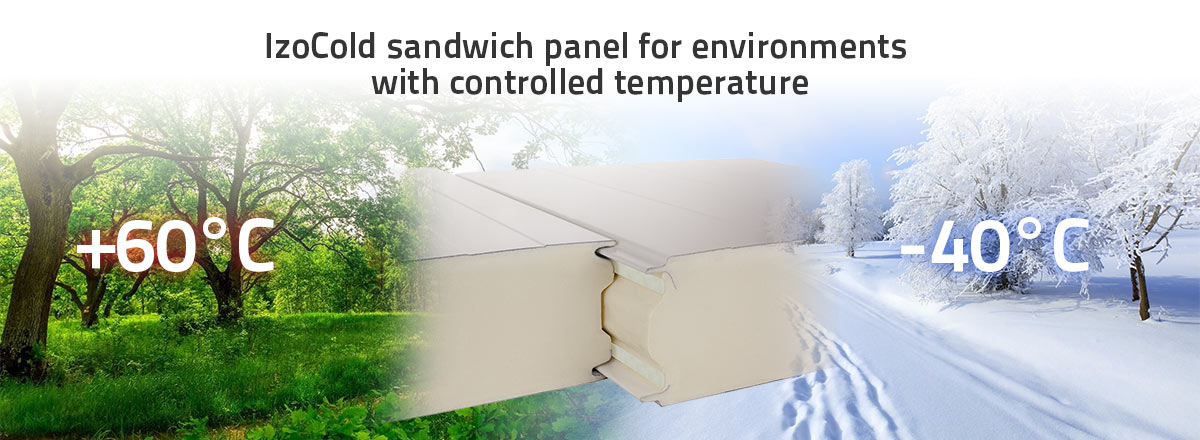

Sandwich panel as a modern solution for cold rooms, can be used on external, internal walls and also as suspended ceilings. Cold room sandwich panels can be used in temperatures as low as -40oC.

Shape of labyrinth core joint of our design provides perfect thermal insulating power, eliminating negative effect of thermal bridge. Wide range of thickness of cold store sandwich panels ensures meeting of requirements for thermal barriers and generates real savings resulting from no heat losses. Sandwich panel is suitable for use both in industry and agriculture what is confirmed by numerous certificates and approvals.

Profiling

With the variety of profile types of Izopanel sandwich panel claddings and a wide selection of paint coats in various colours, our products give a unique character to any building.

NOTE! in BP profile (no profiling), slight corrugation of the surface is possible; the permissible deviation from the flatness is specified in PN-EN 14509:2013.

Colour schemes

Group I – very light colours

Group II light colours

Group III – dark colours

The above colours are for reference only. Izopanel reserves the right to allow differences in colour between presented and actual colours. Widths for maximum lengths for given colour groups are specified in Izopanel Technical Catalogue. Please contact Customer Service for availability.

Table of properties

| Mechanical properties | |||||||||||||||

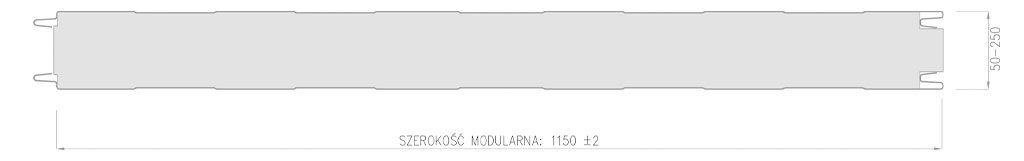

| thickness | 50 | 60 | 75 | 80 | 100 | 120 | 125 | 140 | 150 | 160 | 175 | 180 | 200 | 250* | |

| modular width [mm] | 1150 | ||||||||||||||

| total width [mm] | modular width+18mm | ||||||||||||||

| length [mm] | 2000-13000* | ||||||||||||||

| weight 0,4/0,5 [kg/m²] | 8,4 | 8,6 | 8,8 | 8,9 | 9,2 | 9,5 | 9,6 | 9,8 | 9,9 | 10,1 | 10,3 | 10,4 | 10,7 | 11,4 | |

| weight 0,5/0,5 [kg/m²] | 9,3 | 9,4 | 9,7 | 9,7 | 10,0 | 10,3 | 10,4 | 10,6 | 10,8 | 10,9 | 11,2 | 11,3 | 11,5 | 12,3 | |

| Insulating power | |||||||||||||||

| U [W/m²K] | 0,74 | 0,62 | 0,51 | 0,46 | 0,38 | 0,31 | 0,31 | 0,27 | 0,26 | 0,24 | 0,22 | 0,21 | 0,20 | 0,16 | |

| Burning behaviour | |||||||||||||||

| fire resistance | – | – | |||||||||||||

| reaction to fire | – | ||||||||||||||

| fire propagation | NRO | ||||||||||||||

| Acoustic properties | |||||||||||||||

| acoustic resistance coefficient: | |||||||||||||||

| RW [dB] | NDP | ||||||||||||||

| RA1 [dB] | NDP | ||||||||||||||

| RA2[dB] | NDP | ||||||||||||||

| acoustic absorption coefficient αw | – | ||||||||||||||

| Leakproofness | |||||||||||||||

| Air permeability | ≤ 1,5m3/h*m2 at pressure difference 50 Pa | ||||||||||||||

| Blowing rain resistance | A class - absolute leakproofness at 1200 Pa | ||||||||||||||

* AT-15- 5340/2014 applies to sandwich panels with panel thickness of: 50, 60, 75, 100, 125, 150, 200, 250 [mm]

** maximum length depending on the panel colour

EN

EN PL

PL RU

RU NO

NO FI

FI LT

LT LV

LV ET

ET SV

SV