Skylights

SKYLIGHTS

Skylights – unique solution for lighting of an industrial facility, livestock buildings, etc. with (natural) daylight.

Manufacture:

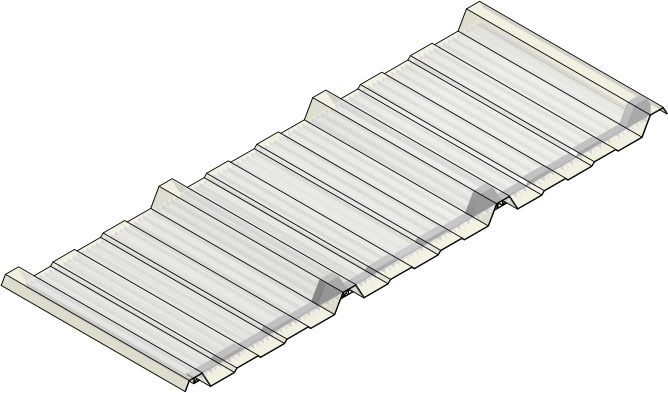

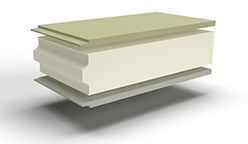

They are made of modern resin-glass composite and polycarbonate and fit perfectly to the shape of roof covering formed by sandwich panels.Outer layer of resin-glass composite i s made of polyester resin (gelcoat) which forms a smooth and aesthetic coating of higher resistance to weather conditions and UV-radiation.

| Parameters | Value |

| Material | Resin-glass composite with polycarbonate of 25mm in thickness (on request polycarbonate of 16mm and 20mm in thickness is available) |

| Length of opening | 7.0m (maximum length of cladding 7.2m) Skylights can be joined in length-wise direction directly on the site. |

| Recommended minimum roof inclination | 10% (for 20cm overlapping) |

| Maximum support spacing | 1.5m |

| Thickness | 30mm + rib length |

| Weight | 5.9kg ± 5% |

| Heat transfer coefficient | Standard U = 1.5 W/M2K for polycarbonate thickness 25mm |

| Light transmission | 50% ± 5% |

Advantages and use

Advantages:

– Daylight illumination of facility interior.

– May be used instead of electric lighting if installed on roof covering over an area of 7-15% – Eliminates loss of heat accumulated on the facility and limits excess increase in temperature which is caused by sunlight, and thanks to a chamber design also provides illumination.

Use:

– Industrial facilities with inclined roofs. i.e. with inclination angle of more than 10%, provided with heat-insulation covering formed by sandwich panels.

– Roof skylight may be installed as spot illumination or row lighting to provide masking between roof ridge and eave, in the centre of roof surface, by roof ridge, between roof surface centre and eave.

EN

EN PL

PL RU

RU NO

NO FI

FI LT

LT LV

LV ET

ET SV

SV